Comprehensive Overview of Wastewater Engineering and Sewer Construction

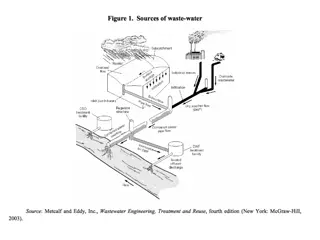

This detailed content covers various aspects of wastewater engineering, including sewer appurtenances, construction, maintenance, and house drainage systems. It also delves into rainwater harvesting methods and provides references for further study. The procedure for laying sewers, from setting out the center line to alignment and gradient determination, is explained step by step. The construction process involving excavation, timbering, laying and joining pipe sewers, testing, and backfilling is outlined in a systematic manner.

- Wastewater Engineering

- Sewer Construction

- House Drainage Systems

- Rainwater Harvesting

- Engineering Procedures

Uploaded on Sep 15, 2024 | 0 Views

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Wastewater Engineering (Environmental Engg.-II) Rajesh Bhagat BE (Civil Engg) GCOE, Amravati Achievement: Selected Scientist, NEERI-CSIR, Govt. of India. MTech (Env. Engg) VNIT, Nagpur GATE Qualified Three Times. UGC - NET Qualified in First Attempt. In 2020, Recognized by SWAYAM, NPTEL & IIT: 1) Discipline Star 2) NPTEL Believer 3) NPTEL Motivated Learner Topper of PhD Course Work at UGC-HRDC, RTMNU Nagpur. Selected Junior Engineer, ZP Washim. Three Times Selected as UGC Approved Assistant Professor: 1) Assistant Professor, PCE, Nagpur. 2) Assistant Professor, Cummins College of Engg. for Women. 3) Assistant Professor, YCCE, Nagpur. Mobile No.:- 8483002277 / 8483003474 Email ID :- rajeysh7bhagat@gmail.com Website:- www.rajeysh7bhagat.wordpress.com

UNIT-II 1) Sewer Appurtenances manholes, street inlets, storm water overflows, inverted siphons, flushing and ventilation. 2) Construction and Maintenance of Sewers, equipment s for maintenance & safety equipment s. 3) Sewage Pumping. 4) House Drainage Systems, sanitary fitting and appliances, traps function and types, anti-syphonage, inspection chambers, Storm water drainage. 5) Rainwater Harvesting for individual houses & Different Methods. 2

References:- 1. B.C. Punmia, Waste Water Engineering, Laxmi Publication 2. S.K. Garg, Environmental Engineering Vol II, Standard Publication 3. G.S. Birdie, Water Supply & Sanitary Engineering, Dhanpat Rai Pub Company 4. M.N. Rao & H.V.N. Rao, Air Pollution, McGraw Hill Publication. 5. M.J. Machghee, Water Supply & Sewage, McGraw Hill Publication. 6. Dr. P N Modi, Sewage Treatment & Disposal & Wastewater Engg., Rajsons Publications Pvt. Lts

Construction of Sewer or Procedure for Laying Sewer: 1) Setting out sewer centre line 2) Alignment & gradient of sewer 3) Excavation of trenches 4) Timbering 5) Dewatering 6) Laying & joining of pipe sewers 7) Testing of pipe Sewers 8) Backfilling of trenches 4 4

Construction of Sewer or Procedure for Laying Sewer: Setting out sewer centre line: 1) First step in laying of sewers. 2) Laying of sewer carried out from the tail end or outfall end, & proceeding upwards. 3) Sewer lines are marked & pegs are placed at regular interval 7.5 or 15m.. Setting out alignment & gradient: 1) Setting out alignment is carried out starting from their outfall ends towards their starting points. With this advantage of utilization of the tail sewers even during the initial periods of its construction is possible. 2) The points are located where manholes are required to be constructed as per drawing, i.e., L-section of sewer. 3) Temporary benchmark is established with the help of levels. 5 5

Construction of Sewer or Procedure for Laying Sewer: Excavation of trenches: 1) Trenches are excavated manually or mechanically. 2) The width of trench depends upon the diameter of sewer & depth of sewer line below the ground level. 3) The width of the trench at the bottom is generally kept 15 cm more than the diameter of the sewer pipe, with minimum 60 cm width to facilitate joining of pipes. Timbering of Trenches: 1) In case of loose soil the sides will collapse and hence shoring and strutting is necessary. 2) This is also necessary to prevent caving to reduce danger to workman. Dewatering of Trenches: 1) Trenches should not be wet & muddy while or before jointing of sewer. In such case 6 dewatering is done by pumping. 6

Construction of Sewer or Procedure for Laying Sewer: Laying & Jointing of Pipes Sewers: 1) After setting a sight rail, centre line of the sewer is transferred to the bottom of the trench by driving small pegs at an interval of 3m or so. 2) Before laying sewer, it should be checked for any defect. 3) The trench is excavated between two manholes and the bedding layer of concrete is provided for soft soil while in case of rocky or hard soil, no bedding. 4) The sewer pipes are then lowered down in to the trench either manually or with the help of machines for bigger pipe diameters. 5) The levels of invert of sewer are checked by boning rod or traveler. 6) After completing the laying of sewer pipe between two manholes. Further excavations are carried out for laying of sewer pipe between the next consecutive manholes. The process is continued form the outfall end of the sewer towards the starting end till the entire sewers is laid out. 7 7

Construction of Sewer or Procedure for Laying Sewer: Backfilling of Trench: 1) The trench should be backfilled only after the laid sewer has been tested and approved for water tightness of joints. 2) To ensure the future safety of sewer, the work of backfilling should be carried out with due care, particularly the selection of soil used for backfilling around the sewer. 8 8

Sewer Testing: The various tests are carried out to check water tightness of the sewer & proper working. Air Test: 1) Particular section is selected & plugs are provided at the upper & lower ends. 2) The air is forced in the pipes by suitable equipments such as pump. 3) Leaky joints are found by applying soap solution. 4) The escape of air from leaky joints formed bubble & which are visible. 5) Then joints are repaired. 9 9

Sewer Testing: The various tests are carried out to check water tightness of the sewer & proper working. Hydraulic Test or Water Test: 1) For this sewer pipe sections are tested between the manholes to manhole under a test pressure of about 1.5 m water head. 2) To carry this, the downstream end of the sewer is plugged and water is filled in the manhole at upper end. 3) The depth of water in manhole is maintained about 1.5 m. 4) The sewer line is inspected and the joints which leak are repaired. 5) In color water test, color water is used & inspected. 10 10

Sewer Testing: The various tests are carried out to check water tightness of the sewer & proper working. Smell Test: 1) Test is similar to air test but in this case air is mixed with some smelling gas. 2) Such air is allowed to pass through the sewer line & escape of air from leaky joints is detected by smell and such joints are repaired. 3) Mercaptans, Mercaptan Sulfide Blends, Sulfur, Nitrogen, Halogen, Helium, Sulfur Hexafluoride (SF6) & Industrial Hydrogen (95% nitrogen, 5% hydrogen) Smoke Test: 1) Test is similar to air test but in this case smoke is used. 2) Smoke is allowed to pass through the sewer line. 11 11

Sewer Testing: The various tests are carried out to check water tightness of the sewer & proper working. Test for Straightness of alignment 1) By placing a mirror at one end of the sewer line and a lamp at the other end. 2) If the pipe line is straight, full circle of light will be observed. Ball Test: it used for any obstruction or blockage. 12 12

Sewer Appurtenances:- Sewer appurtenances are the various essential accessories or devices for the proper maintenances & efficient operation of sewerage system. These appurtenances are necessary because if simply sewers are laid, the sewage can not flow in it continuously for longer time. After some, it will be choked up and will require cleaning of sewers. The various appurtenances are as below: 1) Manholes. 2) Drop Manholes. 3) Flushing Tanks. 4) Lampholes. 5) Street Inlets. (Inlet) 6) Catch Basin. (Inlet) 7) Ventilating Shaft. 8) Grease & Oil Traps 9) Inverted Siphons. 10)Storm Water Regulators.

Manholes:- 1) It is a construction made to connect the ground level with the hole or opening made in the sewer line so that a man can easily, conveniently and safely enter through it and carry out the usual maintenances operation. 2) It consists of working chamber, an access shaft & a strong cover on the top. 3) The lower portion of a manhole is known as a working chamber and it provides a working space to carry out cleaning and inspection of sewer line. (Slope, Direction, More sewers) 4) Access shaft provides access to the working chamber. 5) The manhole cover of RCC is provide to cover the opening.

Drop Manholes:- 1) When it is uneconomical or impracticable to arrange the connection with 60 cm of invert of the sewer and manhole, then vertical shaft is constructed outside the manhole chamber through which the sewage of branch sewer is allowed to enter the manhole. 2) Such a manholes which drop the level of invert of the incoming sewer by providing a vertical shaft are called drop manhole. 3) The main purpose of drop manhole is to avoid the splashing of sewage on man working & on the masonry work. 4) Larger the diameter of the sewer the greater may be the spacing between two manholes. http://3.bp.blogspot.com/-co4gi_I3S4w/T6LFYajvUJI/AAAAAAAAAKU/o4B6t8sQXds/s640/drop+manhole.jpg

Flushing Tank:- 1) An arrangement to hold and then throw water into the sewer for the purpose of flushing 2) When the gradient of the sewers are flat and velocity of sewage is low, the suspended matter starts settling and causes clogging of sewer, at such places, where self cleansing velocity is not available, flushing tank are provided to flush the sewer. 3) Hand Operated Flushing Tank & Automatic Flushing Tank. 4) Flushing tanks are also provided near the dead ends of sewers. 5) The quantity of water added in one flush is about 1600 litres. 6) Flushing tanks should have sufficient capacity to hold water temporarily, to serve the required purpose. 7) Generally, the capacity of flushing tank is kept equal to 1/10 th of the cubical contents of the sewer line served by it.

Lampholes:- 1) A lampholes are the opening or holes are constructed in a sewer for the purpose of lowering a lamp inside it. 2) It is a vertical stoneware or concrete pipes which are connected to the sewer line through a tee junction. 3) The pipes are surrounded by concrete to make them stable. 4) At the ground level, the manhole cover with frame is provided to take up the load of traffic.

Street Inlet:- 1) An inlet is a device meant to admit the storm water or surface wash and convey it into a storm sewer or a combined sewer. 2) Inlets are not necessary in case of separate sewers 3) Inlets are of three types : a. Curb inlet or vertical inlet b. Gutter inlet or horizontal inlet c. Combined inlet 4) Inlet may either depressed or flush depending upon their elevation with respect to the pavement surface. 5) A maximum spacing of 30 m is recommended on straight roads. 6) Inlets are also located at Street intersections. 7) A curb inlet does not interface with the flow of traffic.

Street Inlets:- 1) It is an opening through which storm water and surface water flowing along the street are admitted and conveyed to the storm water sewer or combined sewer by means of pipes. 2) These are placed at the road, gutters, generally at street junctions. 3) It should provide in a such way that it will not cause any interference with the traffic. 4) Curb Inlets, Gutter Inlets & Combined Inlets.

Catch Basin or Catch Pit:- 1) It is a special type of inlet, in which a basin is provided which allows grit, sand and debris etc. to settle out which flowing in with storm water. 2) The outlet is usually trapped to prevent escape of odors from the sewers and to retain floating matter. 3) The settled matter is taken out periodically.

Inverted Siphons:- 1) When a sewer line dips below the hydraulic grade line, it is called an inverted siphon. 2) The purpose is to carry the sewer under the obstruction, such as roadway, railway, stream, river etc., and regain as much elevation as possible. 3) The sewage through such a pipe line (or inverted siphon) will flow under pressure which is greater than atmospheric.

Inverted Siphon:- Ventilating Shaft:-

Grease and Oil Traps: 1) They are specially built chambers on the sewers to exclude grease and oil from sewage before they enter the sewer line. 2) Such traps are located near those sources, such as automobile repair workshops, garages, kitchens of hotels, oil and grease industries, which contribute grease and oil in their waste waters. 3) Grease and oil entering into the sewer lines will stick to the interior surface of the sewer conduit and will become hard, thus causing obstruction to flow. 4) Presence of oil & grease in sewer increases the possibilities of explosion in sewer lines. 5) Presence of oil & grease in the wastewater causes difficulties in treatment of waste water. 6) Presence of oil and grease on the surface of wastewater prevents oxygen to penetrate, due to which aerobic bacteria will not survive and hence anaerobic condition will develop. This will give rise to bad odors.

Clean Out: (Water & Flexible Rod) 1) A clean out is an inclined pipe with its one end connected to the underground sewer line and the other end brought upto ground level, with a proper cover at the top. 2) They are generally provided at upper ends of lateral sewers in place of man holes. 3) They are meant for clearing out the lateral sewers. 4) For cleaning purposes, the cover is taken out and water is forced into the clean out pipe. 5) For removing larger obstruction, flexible rod may be inserted or other methods are adopted.

Storm Regulators:- Storm regulators are the appurtenances which are constructed for combined sewerage 1) system, so as to permit the diversion of storm water when the discharge exceeds a certain value. The excess water is diverted to a natural stream or river 2) In a combined system, the D.W.F. may be very small and the quantity of storm water is large. Generally, a combined sewer is designed for a discharge equal to 3 to 6 times the dry weather flow. 3) Sometimes, when the intensity of rain is more, the quantity of storm water becomes enormous. This excess quantity is therefore diverted through the use of storm regulators Thus the storm water regulators, also some times called as overflow devices, prevent 4) overloading of sewers, pumping stations, treatment plants and other disposal arrangements. 1. Over Flow Weirs (Side Flow Weirs). 2. Leaping Weirs (Jumping Weirs) 3. Siphon Spillways.

Over Flow Weirs : 1) very common device and consists of a masonry chamber, with an overflow weir built in it at a place where a sewer approaches a natural watercourse. 2) The object is to keep the discharge to the storm water down to a predetermined maximum and allow the surplus to overflow to the water course. 3) The overflow weirs (side weirs) may be single acting (or single side) or double acting (or double sides). Double Sided Overflow weir

Leaping Weir or Jumping Weir:- 1) Special device by way of which excess wastewater (during storm) is allowed to escape to a watercourse, while the designed flow is permitted to flow to the intercepting sewer. 2) Consists of an opening in the invert of the combined sewer, and through this opening the normal flow is diverted into the intercepting drain while the excess flow leaps over the storm drain leading it to a nearby stream.

Siphon Spillway:- 1) The overflow weirs described earlier require considerable length, resulting in high cost of construction. 2) Work on the principle of siphonic action. 3) Siphon spillways are very effective since they have high discharging capacity. 4) The spillway is very sensitive, automatic in operation and diverts more flow in lesser time.

House Drainage System:- The foul matter should be quickly removed away from the sanitary fixtures so as to avoid the putrefaction and production of bad smelling gases. The drainage system should be able to prevent the entry of gases, vermin etc from the sewer into the building. Requirements of Good Drainage System in Buildings: 1) The drainage pipes should be strong and durable. 2) The pipes should be of non-absorbent materials. 3) The pipes and joints should be airtight to prevent the leakage of waste water or gases. 4) The network of pipes should have sufficient accessibility for inspection & cleaning. 5) The levels of building, sewer and other points of outlet should be fixed accurately. 6) As per as possible drains should not pass under the buildings. 7) The drains should be given proper ventilation to avoid air locks and syphonage. 8) The system should have traps at all necessary points.

Sanitary Fittings:- The sanitary fittings are required in house drainage for the efficient collection and removal of waste water from the house to house drain. The following are some of the sanitary fittings. 1) Traps. 2) Water closets. 3) Flushing cisterns. 4) Urinals. 5) Inspection chambers. 6) Wash basins. 7) Sinks. 8) Bath tubs etc.

Traps:- - A trap is a depressed or bent sanitary fitting which always remains full of water (water seal). The function of a trap is to prevent the entry of bad smelling gases into the house. The effectiveness depends upon the depth of water seal. ( 25 to 75mm ) Requirements of Good Trap:- 1) It should be capable of being easily cleaned. 2) It should be easily fixed with the drain. 3) It should be of simple construction. 4) It should possess self-cleansing property. 5) It should possess adequate water seal to fulfill the purpose of installation. 6) The internal and external surfaces should be of smooth finish. 7) It should be free from any inside projection which are likely to obstruct the passage of flow of sewage.

Types of Traps:- Classification according to shape:- 1) P-Trap. 2) Q-Trap. 3) S-Trap. 36

Types of Traps:- Classification according to use:- 1) Floor Trap:- Made of cast iron with grating at top and used to for admitting wastewater from floor of bath & kitchen. This trap is also known as Nahni Trap 2) Gully Trap:- Made of stoneware & caste iron. Wastewater from sinks, bath, etc., enter through back inlet & unfoul water from the sweeping of rooms, courtyards, etc. enter from the top, where coarse screen is fitted to check the solid matter.

Types of Traps:- Classification according to use:- 1) Floor Trap:- 2) Gully Trap:- 3) Intercepting Trap:- It is provided in inspection chamber outside the house to prevent the entry of foul gases from the street sewers to the houses through the house drains. This trap has water seal of about 100mm.

Types of Pipes Used in House Drainage:- 1) Soil Pipe:- Important section of house drainage system in house. 2) Vent Pipe:- Essential for ventilation purpose. 3) Rainwater Pipe:- Collect the rain water from the roof. 4) Fresh Air Inlet Pipe:- Provide for fresh air in the last manhole which connects the house drain with public sewer. 5) Anti-siphonage Pipe:- This type of pipe is provided not to be happen the siphonic action.

Safety Equipments:- 1) Gas Mask:- 2) Oxygen Breathing Apparatus:- 3) Portable Lightening Equipments:- 4) Portable Air Blow:- 5) Inhalators :- 6) Safety Belt:-

System of House Plumbing:- Following are three major system adopted in plumbing of drainage work in a building. 1) Single Stack System:- A single vertical soil pipe is fixed & all the waste matter from baths, kitchens, water closet etc. is discharged into it. It also act as a vent pipe. The single stack system is economical but it is entirely effective in the depth of water seal only. 2) One Pipe System:- 3) Two Pipe System:-

System of House Plumbing:- Following are three major system adopted in plumbing of drainage work in a building. One Pipe System:- Only one pipe with a ventilation pipe is provided which collects both the foul soil waste as well as unfoul waste from the building. For multistory building, lavatory blocks of various floors are so placed one over the other.

System of House Plumbing:- Following are three major system adopted in plumbing of drainage work in a building. Two Pipe System:- Two sets of pipes are laid. The soil fixture such as urinal & WC are connected to the vertical soil pipe. Waste matter from baths, kitchen, etc. are connected by another vertical waste pipe. Soil pipe & waste pipe requires separate vent pipe hence requires four pipes & therefore becomes costly. Two pipe system is better than other system of plumbing for efficient conveyance of sanitary waste with minimum of risk. One pipes system has a more economical layout of pipes but requires sufficient safeguard, include proper ventilation, adequate water seal and direct connection between the sanitary fixture & soil pipe to make drainage effective. Now days single stack system mostly used on grounds of economy easy planning of plumbing system.

Pumping of Sewage:- In sewerage system at some places the sewage can not flow under its gravitational force only & it requires its lifting. Why it necessary to pump the sewage in sewerage system:- 1) In low laying areas sewage can not flow by gravity into mains & submains, therefore sewage need to pump from lower branch to main sewer. 2) When basement are provided in the buildings, the sewage is pumped to the sewer line. 3) When ground is flat and not getting self cleansing velocity. 4) At the treatment plant to rise it upto the plant for treatment. 5) To lay the sewer along the ridge of hill or obstruction so as to avoid the construction of a tunnel. 6) At the outfall, if level of water course is higher that level of outlet of sewer.

Types of Pumps:- 1) Centrifugal Pump 2) Reciprocating Pump 3) Air Lift Pump or Pneumatic Ejectors Why sewage pumping is different from water pumping:- ( Problems in Sewage Pumping) The pumping of sewage is not as simple as pumping of water. 1) Foul characteristics. 2) Suspended matter & floating matter can clog the pumps. 3) Organic & inorganic matter can cause corrosion & erosion. 4) Disease bacteria may cause health hazards. 5) Sewage flow is continuously varying. 6) Larger size sump well can not be constructed otherwise organic & inorganic matter will settle in the bottom & produces foul smell as well as choking.

Centrifugal Pump :- 1) Most commonly used for pumping sewage. 2) Easily installed in pits & sumps. 3) Easily transport the suspended matter present in the sewage. 4) It consist of a revolving wheel called impeller which is enclosed in an air tight casing to which suction pipe & delivery pipe or rising main are connected. 5) Radial Flow Pump, Mixed Flow Pump & Axial Flow Pump.

Centrifugal Pump :- 1) A spiral shaped casing called volute casing is provided around the impeller. 2) At the inlet to the pump at the centre of the casing a suction pipe is connected, the lower end of which dips into the liquid in the tank or sump from which the liquid is to be pumped or lifted. 3) At the outlet of the pump on the delivery pipe a delivery valve is provided. 4) A delivery valve is a sluice valve or gate valve which is provided on order to control the flow of liquid from the pump into the delivery pipe.

Reciprocating Pump:- 1) This pump are much less employed these days for sewage pumping, because of their high initial cost, difficult in maintenance and greater wear and tear of valves. 2) It may be used for pumping of difficult sludges & large quantity of sewage against low heads after passing the sewage through screen with 20 mm spacing. 3) Two types:

Air Lift Pump or Pneumatic Ejectors:- 1) This pump are used for pumping or lifting small quantities of sewage. 2) It is used where centrifugal pump of small capacity is likely to clog. 3) Pneumatic ejectors use compressed air for lifting sewage.