Effective Methods of Composting for Sustainable Soil Enrichment

Composting is a natural process of organic matter decomposition, beneficial for improving soil quality. The Bangalore Method, Construction of Pit, Filling the Pit, Modified Bangalore Method, and Padegaon Method are efficient techniques used to produce high-quality compost for agricultural purposes.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

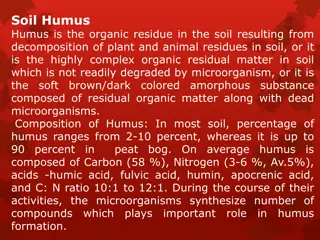

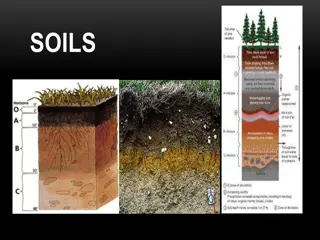

COMPOSTING Composting is the natural process of rotting or decomposition of organic matter by microorganisms under controlled condition .Compost is cheap, easy to make and is very effective material that can be added to soil to improve soil and crop quality.

Methods Of Composting The Bangalore Method This method of composting was developed in Bangalore in India by Acharya. In this method initially the decomposition is done aerobically followed by anaerobic decomposition and this method is also called as hot fermentation method.

Construction Of Pit : About 1m deep pits are dug and the breadth and length of the pit depends n the availability of land and the type of material to be composted. The pit should preferably have sloping walls and a floor of 90cm slope to check water logging.

Filling The Pit : Organic residues and night soil are put in alternating layers and the pit is covered a 15 20 cm thick layer of refuse after filling. The materials are allowed to stay in the pit without turning and watering for 3 months after the initial aerobic composting for about 8- 10 days the material undergoes anaerobic decomposition at very slow rate and it takes about 6-8 months to obtain the finished product.

Modified Bangalore Method: It is a combination of both aerobic and anaerobic method. To make the compost at high temperature after the heap is erected, hollow bamboo pipes are inserted into it both vertically and horizontally. In 2-3 days the temperature of the heap rises to 60-70 degree Celsius. The poles are then removed and the heap is plastered with mud. The plaster is broken after 15 days and the heap is turned thoroughly. The heap is replaced and let for natural decomposition. The compost get manure in about 2 months.

Padegaon Method This method is recommended for composting resistant substrates like sugarcane trash and cotton stubbles. These materials are chopped into 30cm size particles and compressed to make a 30cm thick above ground layer. This layer is soaked with slurry consisting of wood ash, cow dung and soil. 4 or 5 such layers are added to the pile . The complete heap is about 1.5m high, 2m wide and of length as necessary. Since the material is very resistant to decay the heap is turned each month and sufficient water Is added to it to keep it moist. The material is ready for use in about 5 months.

Coimbatore Method The composting is done in pits of different sizes depending on the waste material available. A layer of waste material is first laid in the pit. It is moistened with a suspension of 5-10kg cow dung in 2.5-5.0 L of water and 0.5-1.0kg fine bone meals sprinkled over it uniformly. Similarly layers are laid one over the others till the material rises 0.75m above the ground level. It is finally plastered with mud and left undisturbed for 8-10 weeks. Plaster is then removed, material moistened with water, given a turning and made into a rectangular heap under a shade. It is left undisturbed till it used.

Trench Method Construction Of Pit: The site selected for this type of pit should be at high level so that no rain water gets in during the monsoon season. It should be near to the cattle shed and a water source. A temporary shed may be constructed over it to protect the compost from heavy rainfall. The pit should be about 1m deep, 1.5- 2m wide and of suitable length.

Filling the pit: The material from the cattle shed is spread evenly in the pit in layers of 10- 15cm. On each layer is spread slurry made with 4.5kg dung, 3.5kg urine earth and 4.5kg of inoculum taken from 15 days old composting pit. Sufficient quantity of water is sprinkled over the material in the pit to wet it. The pit is filled in this way layer by layer and it should not taken longer than 1week .

Turning: The material is turned 3times during the whole period of composting the first time 15days after filling the pit, the second after another 15 days and the third after another month. At each turning the material is mixed thoroughly, moistened with water and replaced in the pit.

Heap method Construction of site: The compost may be prepared in heaps above ground and protected by a shed during rainy seasons. The basic Indore pile is about 2m wide at the base, 1.5m high and 2m long. The sides are tapered so that the top is about 0.5m narrower in width than the base. A small bund is sometimes built around the pile to protect it from wind, which tends to dry the heap.

Formation of the Heap: The heap is usually started with a 20cm layer of carbonaceous material such as leaves, straw, sawdust, woodchips and chopped corn stalks. This is then covered with 10cm of nitrogenous material such fresh grass, weeds or garden plant residues or dry manure. The pattern of 20cm carbonaceous material and 10cm of nitrogenous material is followed until the pile is 1.5m high and the material is normally wetted so that it may feel damp but not water logged. The pile is sometime covered with soil and hay to retain heat and is turned at 6 and 12 week intervals.

The heap are covered with thin plastic sheets to retain heat and to prevent insect breeding. Shredding of the material speedup decomposition significantly. Most material can be shredded by running over them several times a rotary mower. When sufficient nitrogenous material is not available a green manure or leguminous sun hemp is grown on the fermenting heap by sowing seeds after the first turning. The green matter is then turned in at the time of the second mixing. The process takes about 4 months to complete.