Addressing Consumption-based Emissions: Perspectives on Materials Efficiency and Innovation

This workshop delves into the importance of addressing consumption-based emissions, with perspectives from both Chinese and European experts. Key topics include the role of carbon pricing, inclusion of consumption in carbon pricing mechanisms, and strategies for reducing emissions from carbon-intensive materials like cement and steel. The presentation emphasizes the need for innovation and efficiency in industrial processes to achieve deep decarbonization goals. Various emission reduction opportunities and determinants of technology adoption are also discussed.

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

Carbon-Cap workshop: Addressing Consumption-based Emissions: A Chinese Perspective Materials efficiency and innovation in building and vehicles-a European Perspective Application of consumption-based improvement options Karsten Neuhoff Institute of Policy and Management, Chinese Academy of Sciences, 10.11.20215

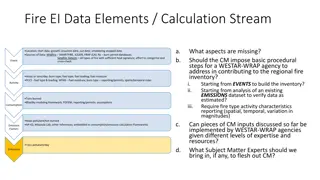

1 2 3 4 Motivation The role of carbon pricing Inclusion of consumption in carbon pricing mechanism Conclusion Inclusion of Consumption of carbon intensive materials in emission trading systems

1. Industrial emissions dominated by production of carbon intensive materials Industrial activities with the highest cost increase from carbon pricing (Example UK, carbon price 20 /t CO2and electricity price increase 10 /MWh) Electricity cost increase (blue) cost for buying all allowances (grey) relative to gross value added. Production of cement and steel alone accounts for 38% of European industry emissions: Important to realize mitigation opportunities of selected carbon intensive materials Production and use of these materials justifies focused attention Inclusion of Consumption of carbon intensive materials in emission trading systems

1. Three groups of emission reduction opportunities for carbon intensive materials Group 2: Carbon focused process innovation Group 1: Fuel shifting and production efficiency Group 3: Estimates for cement sector in different road maps: Material efficiency and substitution By what percentage can cement sector reduce its emissions 60% 40% IEA (low demand scneario) Ecofys/WWF 20% 0% UK Committee on Climate Change Cembureau Efficiency Biomass Pre-treated (waste) Substitution Energy Substitution/ Capture and Cement Based Efficient Use (waste) of Cement Clinker Innovative Storage Materials Carbon Mineral Products Association WBSD/ECRA Technology Report Main activity to date, only limited potential remaining No progress Largely unexplored (excemption clinker substitution) Similar picture for other material sectors like steel. Mitigation options from all groups required for deep decarbonization (G7) , 80-95% reductions (EU). But very limited progress with Group 2 and 3. Inclusion of Consumption of carbon intensive materials in emission trading systems

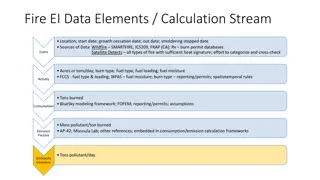

1 Determinants of pick-up rates of new technologies, materials, practices .. Internal factors and individual-level context Socio-cultural context Institutional, economic and technological context Knowledge, competence and Infrastructure and Technology Accessibility and Affordability Determinants of pick-up rate of improvement option by potential implementers (consumers, retailers ) Preferences, intentions and Identity and social status Policy and institutions Socio-demographic characteristics Substitutability information attitudes Habits Policy measures w/ influence on pick-up rate of improvement option Policy measure 1 Policy measure 2 Policy measure 3 Barriers to implementation of improvement options 5 Sebastian Petrick

Policy measures to trigger consumer responses for materials sector: C-Cap identified policies with high feasibility/acceptance/performance 1 Informational Instruments Regulatory and Administrative Instruments Economic Instruments Enabling infrastructure and institutional Approved technologies lists Mandatory Regulatory standards Carbon intensive materials charge Infrastructure improvement Mandatory Recycling requirements and waste targets Business emission agreements / allowances Information campaigns supply chain procurement requirements Voluntary Rankings and awareness campaigns Business emission agreements Inclusion of Consumption of carbon intensive materials in emission trading systems

1 Alternative building materials individual level context Preferences, intentions and attitudes Knowledge, competence and information Habits Negative perception of and prejudices towards alternative materials (e.g. fire-resistance of timber) Focus on operational emissions Lack of awareness, environmental aspects found to play a minor role in most consumer decisions Slow adaptation by risk- averse communities that are used to conventional methods Established practices Time constraints incentivise familiar copy- paste designs Lack of reliable and comparable information on new materials Unfamiliarity with alternative materials Inability to use the technology (e.g. moderate use of wood in Southern Europe) Barriers to implementation of improvement options 7 Sebastian Petrick

1 Alternative building materials institutional, economic and technological context Policy and institutions Infrastructure and Technology Accessibility and Affordability Substitutability Existing building codes Lack of established standards, design guides, tools, standardised details Small industries cannot compete against established industries economics of scale Supply chain limitations Functionality of alternative materials (e.g. fire-resistance of timber) Higher costs of new materials Increased insurance costs Uncertainty premium on new options by intermediaries Local availability of materials and technology Cost of additional training and research Shortage of specialist skills Barriers to implementation of improvement options 8 Sebastian Petrick

1 2 3 4 Motivation The role of carbon pricing Inclusion of consumption in carbon pricing mechanism Conclusion Inclusion of Consumption of carbon intensive materials in emission trading systems

2. Carbon pricing can in principle create incentives for all mitigation opportunities Global Full Emissions reductions through Group Role that carbon pricing can play: Role for complementing policies Auction- ing Incentives for improving carbon efficiency of materials production Fuel shifting and production efficiency 1 Consistent mechanism including clarity on costs allocation Carbon focused process innovation (Co-) funding for Research, Development, Demonstration Adjust norms, standards, training for new practices/materials 2 Makes efficient material use / low carbon material competitive Material efficiency and substitution 3 With global converging carbon pricing, all allowances can be auctioned also in materials production. In such a scheme carbon price creates the full incentive for all Groups of mitigation options. Inclusion of Consumption of carbon intensive materials in emission trading systems

2. Free allocation for carbon leakage protection limits incentives from carbon price Full incentive Basis of free allowance allocation Some incentive 3. Recent production and historic intensity dynamic 4. Recent production and benchmark 2. Historic production and benchmark Small incentive Emissions reductions through Group 1. Historic emissions Role of carbon pricing Incentives for improving carbon efficiency of materials production Fuel shifting and production efficiency 1 Consistent mechanism including clarity on costs allocation Carbon focused process innovation 2 Makes efficient material use / low carbon material competitive Material efficiency and substitution 3 No matter how allowances are allocated for leakage protection, significant distortions remain: Historic emissions (or intensities) as basis for free allocation, discourages efficiency improvements. Can be corrected with use of benchmarks. (2 & 4) If based on historic output, then allocation can deviate significantly from emissions. Can be avoided with use of recent production volumes. (3 & 4) But further limits price pass-through for materials efficiency & substitution. (3 & 4) If consumers do not pay for carbon, no perspective for large scale use of CCS-type technologies. Inclusion of Consumption of carbon intensive materials in emission trading systems

2. Adding inclusion of consumption can restore the carbon price and incentives Basis of free allowance allocation Recent production and benchmark + Recent production and historic intensity dynamic Recent production and benchmark IoC Recent production and benchmark Historic production and benchmark Emissions reductions through Group Historic emissions Role of carbon pricing Incentives for improving carbon efficiency of materials production Fuel shifting and production efficiency 1 Consistent mechanism including clarity on costs allocation Carbon focused process innovation 2 Makes efficient material use / low carbon material competitive Material efficiency and substitution 3 Free allocation based on recent production and benchmark eliminates price pass through. Can be corrected with a consumption charge on carbon intensive materials at benchmark rate. Thus, full incentives for mitigation opportunities in Group 2 and 3 are restored. + Inclusion of Consumption of carbon intensive materials in emission trading systems

1 2 3 4 Motivation The role of carbon pricing Inclusion of consumption in carbon pricing mechanism Conclusion Inclusion of Consumption of carbon intensive materials in emission trading systems

3. The mechanism and its incentives: Domestic case Process action How IoC strengthens incentives for mitigation Creation of liability per ton of e.g. steel (benchmark rate times carbon times ton of steel) Group 2: Credible perspective for carbon capture: extra costs allocated to consumers, not (cross-) subsidized Materials production Passing on liability Group 3: Increases profitability of materials efficiency and substitution with charge on carbon intensive materials Liability suspended Manufacturing Release for consumption: Suspended liability becomes due Companies can inform consumers about level of charge to enhance awareness Information on embedded carbon engages consumers Follows model of existing consumption charges (excises) on fuel, tobacco, alcohol etc. Restores incentive for mitigation opportunities in Group 2 and 3. Inclusion of Consumption of carbon intensive materials in emission trading systems

3. No double charging Consumption charge added to product price Free allocation compensates allowance cost Cost of emission allowances Product price Production cost Production cost Production cost With global carbon price, cost of acquiring allowances added to product price. Free allowance allocation at benchmark per (recent) output reduces cost and product price. Consumption charge at benchmark restores situation of auctions with global carbon price. Level playing field maintained, as charge applies to all steel, cement etc. (irrespective of origin). Consumption charge volume equivalent to revenue if allowances are auctioned to industry. Consumers face same cost as in world of global carbon price and full auctioning. Inclusion of Consumption of carbon intensive materials in emission trading systems

3. The mechanism and its incentives: International case Process action Process action Domestic territory Foreign territory Creation of liability per ton of e.g. steel (benchmark rate times carbon times ton of steel) Acquittal of liability upon export Passing on liability Creation of liability upon import based on material weight and benchmark Liability suspended Release for consumption: Suspended liability becomes due Companies can inform consumers about level of charge to enhance awareness No differentiation how and where product was produced No effect on competitiveness of industry: same rules for domestic and foreign products Inclusion of Consumption of carbon intensive materials in emission trading systems

3. The effect of combining benchmark based allocation with IoC Ensures full carbon price incentive for all groups of mitigation options. No competitive disadvantage for companies because all competitors (also close substitutes) are treated the same. With free allocation at full benchmark level robust leakage protection also for high carbon prices and therefore long-term clarity for decarbonization. Inclusion of Consumption of carbon intensive materials in emission trading systems

1 2 3 4 Motivation The role of carbon pricing Inclusion of consumption in carbon pricing mechanism Conclusion Inclusion of Consumption of carbon intensive materials in emission trading systems

4. Conclusion A few carbon intensive materials dominate industrial emissions Three groups of mitigation options are required 1. Production efficiency and fuel shifting 2. Carbon focused process innovation Material efficiency and substitution Multiple determinants for efficient material use / substitutes individual preferences, habits, information regulation, technology performance, access and affordability Policy response: Information, regulatory, economic, infrastructure Example economic instrument: Charge on carbon intensive materials Can impact corporate / private consumption choices Complemented with building codes, demonstration projects 3. Inclusion of Consumption of carbon intensive materials in emission trading systems

Thank you for your attention! DIW Berlin Deutsches Institut f r Wirtschaftsforschung e.V. Mohrenstra e 58, 10117 Berlin www.diw.de Professor Karsten Neuhoff, kneuhoff@diw.de