Caterpillar Cat 225 EXCAVATOR (Prefix 20S) Service Repair Manual Instant Download

Please open the website below to get the complete manualnn//

Download Presentation

Please find below an Image/Link to download the presentation.

The content on the website is provided AS IS for your information and personal use only. It may not be sold, licensed, or shared on other websites without obtaining consent from the author. Download presentation by click this link. If you encounter any issues during the download, it is possible that the publisher has removed the file from their server.

E N D

Presentation Transcript

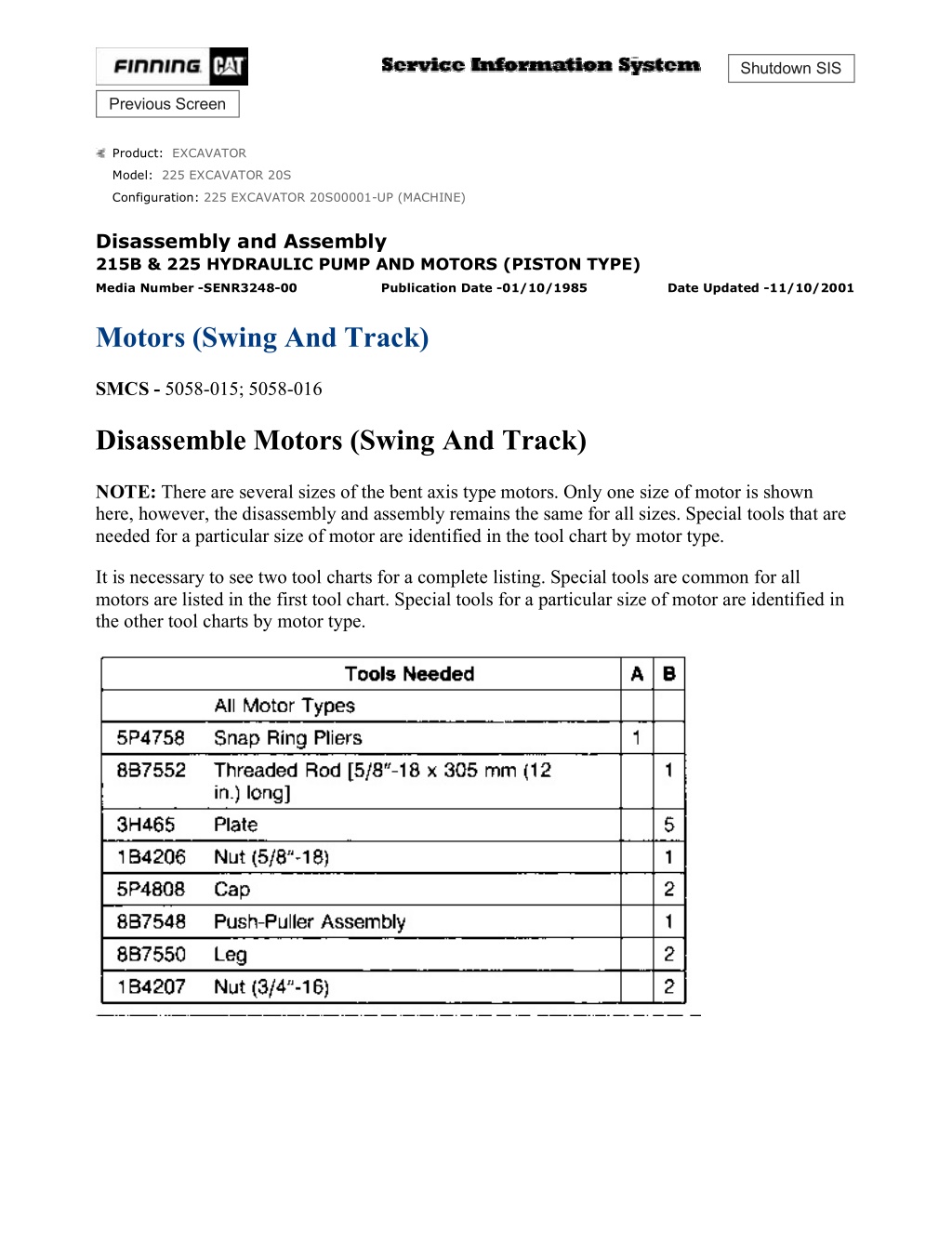

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 1/14 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 225 EXCAVATOR 20S Configuration: 225 EXCAVATOR 20S00001-UP (MACHINE) Disassembly and Assembly 215B & 225 HYDRAULIC PUMP AND MOTORS (PISTON TYPE) Media Number -SENR3248-00 Publication Date -01/10/1985 Date Updated -11/10/2001 Motors (Swing And Track) SMCS - 5058-015; 5058-016 Disassemble Motors (Swing And Track) NOTE: There are several sizes of the bent axis type motors. Only one size of motor is shown here, however, the disassembly and assembly remains the same for all sizes. Special tools that are needed for a particular size of motor are identified in the tool chart by motor type. It is necessary to see two tool charts for a complete listing. Special tools are common for all motors are listed in the first tool chart. Special tools for a particular size of motor are identified in the other tool charts by motor type. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 2/14 START BY: a. remove track motor b. remove swing motor 1. Put plugs in the open oil passages. Clean the outside of the motor thoroughly. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 3/14 2. Remove the plugs from two case drain holes (1). Drain any oil from the motor that remains. 3. Put tape around splined drive shaft (2) to prevent damage to the drive shaft or seals during disassembly of the motor. 4. Tap the cover with a plastic hammer to release some of the pressure against retaining ring (3). Use tool (A), and remove retaining ring (3). 5. Use two screw drivers, and remove front cover (4). Remove the O-ring seal and the shims that are behind front cover (4). NOTE: Pump drive shaft seal (5) will be destroyed if it is removed from front cover (4). 6. Remove lip-type seal (5) from the front cover. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 4/14 7. Turn the motor around, and put alignment marks on the rear cover plate and the motor housing for assembly purposes. 8. Remove six bolts (6) and lockwashers that hold the rear cover plate to the motor housing. 9. Rotate rear cover plate (7) on the locating pin, and remove it from the motor housing. 10. Note the position of locating pin hole (9) on the control plate that the locating pin in rear cover plate (7) was removed from. 11. Remove O-ring seal (8) from the motor housing. 12. Remove control plate (11) from motor housing (12). Note the condition of the bronze surface on cylinder block (10) and the mating surface of control plate (11). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 5/14 NOTICE Use only a puller such as tooling (B) to remove the rotary group. Do not use a slidehammer type puller or damage to the motor may result. 13. Use tooling (B), and remove the rotary group from motor housing (12). Make sure cylinder block (10) does not bind as it is pulled through the motor housing. 14. Remove tooling (B) from rotating group (13). 15. Pull cylinder block (10) from the drive shaft and piston assembly (14). 16. Remove four Bellville washers (16) and spring collar (15) from the center pin bore of cylinder block (10). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 6/14 17. Use a section of pipe or wood blocks, and put the drive shaft and piston assembly in position as shown. 18. Position each piston (18) perpendicular to retaining plate (17), and remove them by pulling straight out. Do this for the seven pistons. The center pin cannot be removed at this time. 19. Check seven pistons (18) at area (X) for scratches and pitting. Make replacements if necessary. Piston rings (19) may break apart during removal from the pistons. If the rings are to be removed, wear eye protection to prevent possible personal injury from flying parts. 20. Use a screwdriver, and remove piston rings (19) from the piston. 21. Remove seven screws (21) that hold retainer plate (17) to the drive shaft assembly. The screws were installed with Thread Lock so they will be difficult to remove. Impact the screw heads first to break the seal, and remove by using additional leverage on the screwdriver as shown. 22. Remove retainer plate (17), center pin (20) and the ring that holds the center pin in place. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 7/14 23. Check center pin (20) for scratches or pitting at areas (Y). Replace the center pin if necessary. Assemble Motors (Swing And Track) NOTE: There are several sizes of the bent axis type motors. Only one size of motor is shown here, however, the disassembly and assembly remains the same for all sizes. It is necessary to see two tool charts for a complete listing. Special tools for a particular size of motor are identified in the first four tool charts by motor type. Special tools that are common for all motors are listed in the last tool chart. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 8/14 https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 9/14 1. Measure the drive shaft and bearing assembly to determine the thickness of the shim that will be used under the shaft seal cover. Refer to the Testing And Adjusting Manual for the proper measuring procedure. The Testing And Adjusting Manual Form Nos. are SENR3109 for the 215B and SENR3110 for the 225 Excavator. 2. Measure the center pin, spring collar, cylinder block, and control plate to determine the proper size spring collar that should be used for assembly. Refer to the Testing And Adjusting Manual for the proper measuring procedure. The Testing And Adjusting Manual Form Nos. are SENR3109 for the 215B and SENR3110 for the 225 Excavator. 3. Put drive shaft and bearing assembly (4) in position on a section of pipe or wood blocks. Put center pin (2), retainer washer (3), and retainer plate (1) in position on drive shaft and bearing assembly (4). 4. Put 6V1541 Quick Cure Primer on seven screws (5), and let it dry. Put 9S3263 Thread Lock on the seven screws, and install them loosely to hold retainer plate (1) to the drive shaft and bearing assembly. Put three pistons (6) in position to align retainer plate (1). Tighten seven screws (5) to a torque of 6 N m (53 lb.in.) for the Type AA2F 63 Motor. Tighten seven screws (5) to a torque of https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 10/14 10 N m (89 lb.in.) for the Type AA2F 80, AA2F 107, and AA2F 131 Motor. Remove three pistons (6) from the assembly. NOTICE All piston rings must be installed with the marks toward the flat end of the piston or the motor will not operate. 5. The piston rings are spherical and must be installed with marks (7) toward the flat end of piston (6). Use tooling (A), and install upper piston ring (8). 6. Use tooling (A), and install the lower piston ring with marks (7) toward the flat end of piston (6). Repeat Steps 5 and 6 for all seven pistons. 7. Rotate the piston rings so the end gaps of the upper and lower piston rings are 180 apart. 8. The spring collar that was selected in Step 2 should be used at this time. Put spring collar (10) and four Bellville washers (11) into the center pin bore of cylinder block (9). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 11/14 9. Put SAE 10W oil on seven pistons (12) and in the piston bores in the cylinder block. Install seven pistons (12) into the cylinder block as shown. 10. Put SAE 10W oil on the center pin and in the center pin bore of the cylinder block. Lay the drive shaft and bearing assembly with the drive shaft horizontal. Lay the cylinder block with the pistons horizontal. Make sure the Bellville washers stay in the proper position when the cylinder block is put in the horizontal position. 11. Align center pin (13) with its bore in the cylinder block and assemble the unit. 12. Hold cylinder block assembly (14) and drive shaft assembly (15) together, and put them in the vertical position. Support them on a section of pipe or with wood blocks. Push each piston into a drive shaft socket through the retainer plate. An audible click is made when each piston is seated properly. NOTICE When all seven pistons are seated properly in the retainer plate sockets, the cylinder block will easily angle to one side. Do not force the cylinder block to angle or damage to the pistons may result. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 12/14 13. Angle cylinder block (14) to one side. 14. Put the entire rotating group in a vise. Allow clearance between drive shaft bearing (16) and the top of the vise for the motor housing when it is installed over the rotating group. NOTICE Do not force the motor housing onto the rotating group or damage to the motor may result. The assembly should be done in one smooth, easy movement. If the housing does not fit over the rotating group easily, the problem should be found and corrected before continuing assembly. 15. Heat motor housing (17) evenly to a temperature of 80 C (176 F). Put the motor housing in position over the rotating group. Move motor housing (17) down over the rotating group, and tilt it to clear the rotating group as it is assembled. Continue until the rotating group bottoms out in the motor housing. A small amount of tapping on the outside of the motor housing may be needed, but do not force the assembly together. Allow the motor housing to cool before continuing assembly. NOTE: If the drive shaft is grooved at the seal contact area, shim material up to 1.0 mm (.040 in.) maximum thickness may be used between lip-type seal (18) and cover (19). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 13/14 16. Use tooling (B), and install lip-type seal (18) into cover (19). 17. The proper thickness of shim (20) was determined in Step 1. Install shim (20). Use 5P960 Multipurpose Grease on O-ring seal (21), and put in position on the shim. 18. Put tool (C) over the drive shaft. Put SAE 10W oil on the lip-type seal, and instal cover (19). It may be necessary to lightly tap the cover into the motor housing. 19. Use tool (D), and install retaining ring (22). 20. Install tooling (E), and pull the rotating group up against retaining ring (22). This puts the rotating group in exactly the correct location within the housing. Remove tooling (E). 21. Put 5P960 Multipurpose Grease on O-ring seal (23), and install it onto the motor housing. 22. Put SAE 10W oil on the bronze surface of control plate (24), and install it into the motor housing. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 14/14 23. Align locating pin (25) on rear cover (26) with the single pin hole in control plate (24). Put rear cover (26) in position on the motor housing. 24. Align the alignment marks that were put on the rear cover and the motor housing. 25. Install six bolts and lockwashers (27), and, tighten to a torque of 49 N m (36 lb.ft.) for the Type AA2F 63 motor. Tighten bolts (27) to a torque of 86 N m (64 lb.ft.) for the Type AA2F 80, AA2F 107 and AA2F 131 motors. NOTICE The motor must be filled with oil before installation or damage to the motor may result. 26. Put plugs in all openings except for one of (two) case drain holes (28) in the motor housing. Put the motor in the position it will be mounted in when it is installed on the vehicle. Use the highest case drain hole, and fill the motor with SAE 10W oil. Install a plug in the case drain hole. END BY: a. install track motor b. install swing motor Copyright 1993 - 2021 Caterpillar Inc. Sat Feb 13 21:38:36 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 1/3 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 225 EXCAVATOR 20S Configuration: 225 EXCAVATOR 20S00001-UP (MACHINE) Disassembly and Assembly SUPPLEMENT FOR HYDRAULIC SYSTEM FOR MACHINES EQUIPPED WITH 4 Media Number -SENR3051-01 Publication Date -01/08/1984 Date Updated -11/10/2001 Pilot Valve SMCS - 5452-15; 5452-16 Disassemble Pilot Valve 1. Put a mark (1) on the body and base. 2. Remove hex-head bolt (2) from body. 3. Carefully pull base (3) away from body (4). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 2/3 NOTE: Seals on the valves may make it hard to pull base off. 4. Remove four outer springs (5). 5. Remove actuator plate (6) and swivel. 6. Remove retainer (7) and plunger (8). NOTE: There are four retainers and plungers. They pull out very easy. The plunger for No. 2 valve is different than the rest. Mark it to be sure it is installed correctly during assembly. 7. Remove plunger (8) from retainer (7). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 3/3 8. Remove valve stem (9) from body. NOTE: All four stems are the same. However, mark each one carefully with the number of the bore shown on the bottom of base (3). Assemble Pilot Valve 1. Assemble the valve in reverse order of disassembly. 2. Put valve stems back in correct bores. 3. Be sure the correct plunger is installed in valve No. 2. The cavity in plunger for valve No. 2 is deeper than the other valves. 4. Do not tighten the swivel too much. A small amount of clearance between the actuator plate (6) and the plungers (8) is needed. 5. Actuate each valve with the actuator plate. If all valves operate freely, valve is ready to be installed in the machine. Copyright 1993 - 2021 Caterpillar Inc. Sat Feb 13 21:39:58 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 1/4 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 225 EXCAVATOR 20S Configuration: 225 EXCAVATOR 20S00001-UP (MACHINE) Disassembly and Assembly 225-235-245 EXCAVATORS OPERATOR'S STATION Media Number -SENR7714-00 Publication Date -01/08/1977 Date Updated -12/10/2001 Door Glass SMCS - 7310-11; 7310-12 Remove Door Glass NOTE: Sliding glass assemblies (groups) are removed and installed with the same procedure. If it is necessary to remove damaged glass, use thick gloves to prevent injury. 1. Put tool (A) in between the two lips of seal (1) as shown. Move tool (A) along the seal to pull the locking lip out away from the cab. Move the tool completely around the circumference of the glass. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 2/4 2. With locking lip out, remove the glass (2) from the opening. Remove seal (1) from the edge of the window opening. Install Door Glass TYPICAL EXAMPLE NOTICE Handle glass carefully. 1. Start along the side of the window panel opening to install seal (3). Install edge (4) of seal over panel (5) with the locking lip toward the outside of the cab. NOTE: When the glass is installed, edge (2) must be over glass (1) as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 3/4 TYPICAL EXAMPLE 2. Install the seal around the circumference of the window opening. Cut the seal to extend past the starting point by .125 in. (3.18 mm) per foot of window opening circumference. Push the ends of the seal together and push them over the body panel to make a tight, smooth joint. 3. Put the lower corner of the glass in the channel of the seal as far as possible. Do not use too much force. 4. Move in both directions from the starting point, lift the glass channel lip and the glass will slip into place. 5. Put a solution of soap and water on the locking lip of the seal. 6. Install the curved end of tool (A) or (7) between locking lip (6) and its groove (8) at any point away from the seal joint. 7. Move the tool along groove (8) as shown. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 4/4 8. Move tool (A) completely around the circumference of the seal, the rubber lip will lock into position around the circumference of the glass. Copyright 1993 - 2021 Caterpillar Inc. Sat Feb 13 21:41:21 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 1/2 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 225 EXCAVATOR 20S Configuration: 225 EXCAVATOR 20S00001-UP (MACHINE) Disassembly and Assembly 225-235-245 EXCAVATORS OPERATOR'S STATION Media Number -SENR7714-00 Publication Date -01/08/1977 Date Updated -12/10/2001 Cab Door SMCS - 7308-11; 7308-12 Remove Cab Door start by: a) remove door glass 1. Open the cab door (1) and fasten a hoist to it. Remove the door hinge bolts, then remove the cab door. Weight of the door is 115 lb. (52 kg). Install Cab Door 1. Fasten a hoist to the cab door and put it in position on the cab. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 2/2 2. Install the door hinge bolts (1). end by: a) install door glass Copyright 1993 - 2021 Caterpillar Inc. Sat Feb 13 21:42:16 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 1/4 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 225 EXCAVATOR 20S Configuration: 225 EXCAVATOR 20S00001-UP (MACHINE) Disassembly and Assembly 225-235-245 EXCAVATORS OPERATOR'S STATION Media Number -SENR7714-00 Publication Date -01/08/1977 Date Updated -12/10/2001 Front Window SMCS - 7310-11; 7310-12; 7310-15; 7310-16 Remove Front Window 1. Slide lower glass (1) up and fasten into position. 2. Release window latches (2) and let window hang free. 3. Remove window hinge bolts (3). https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 2/4 4. Remove front window (4). Install Front Window 1. Put front window (1) in position. 2. Install window hinge bolts (2), but do not tighten. 3. Push front window into place and then fasten the two latches (3). Make any adjustments if necessary, then tighten the hinge bolts. Disassemble Front Window start by: https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 3/4 a) remove front window 1. Remove the sliding glass (1) from the window. Remove the two window locks (2). 2. Remove two screws (3) on each side of frame and remove lower section (4) of frame. 3. Remove glass (5) from the window frame. Assemble Front Window 1. Slide the glass (1) into the window frame. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 4/4 2. Install lower frame (3) and the two screws (2) that hold it. 3. Install two window locks (5) on sliding glass (4). Install the sliding glass (4) into the window frame. end by: a) install front window Copyright 1993 - 2021 Caterpillar Inc. Sat Feb 13 21:43:12 UTC+0800 2021 All Rights Reserved. Private Network For SIS Licensees. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

Suggest: If the above button click is invalid. Please download this document first, and then click the above link to download the complete manual. Thank you so much for reading

225 EXCAVATOR 20S00001-UP (MACHINE)(ZEBP0543 - 00) - Documentation 1/5 Shutdown SIS Previous Screen Product: EXCAVATOR Model: 225 EXCAVATOR 20S Configuration: 225 EXCAVATOR 20S00001-UP (MACHINE) Disassembly and Assembly 225-235-245 EXCAVATORS OPERATOR'S STATION Media Number -SENR7714-00 Publication Date -01/08/1977 Date Updated -12/10/2001 Rear Window SMCS - 7310-15; 7310-16; 7310-11; 7310-12 Remove Rear Window If it is necessary to remove damaged glass, use thick gloves to prevent injury. 1. Put tool (A) in between the two lips of seal (1) as shown. Move tool (A) along the seal to pull the locking lip out away from the cab. Move the tool completely around the circumference of the glass. https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sis... 2021/2/13

https://www.ebooklibonline.com Hello dear friend! Thank you very much for reading. Enter the link into your browser. The full manual is available for immediate download. https://www.ebooklibonline.com